The Union Pacific Big Boy steam locomotive is the world’s largest operating steam locomotive. It was fully overhauled and restored some years ago, and it now runs touring excursions through parts of the country. I was fortunate with the availability to go see her as she passed down from Chicagoland through Villa Grove, Illinois, to Saint Louis, Missouri.

I made two trips of the affair. On the fair afternoon of 9 September, I drove north over many country roads to Block, Illinois, where I set up my tripod and awaited the giant locomotive’s arrival. I found a very… acoustically rousing vantage point from which to capture a small part of her journey through the heart of the US. I found a corner between a silo and a tall metal grain trough. Big Boy’s deep whistle is easily heard for miles away, but no mere audio or video recording can capture the depths to which it fills the body. With two tall structures and a concrete foundation about me, both my ear drums thoroughly quaked. Even my bad ear, which is somewhat less acute than my left due to water damage and standing too close to the battery percussion in college, rattled. I felt the Big Boy’s whistle and deep rumble down the rails in every part of my body. I’m sure ear plugs would have done little to dampen the acoustic experience, and I wouldn’t have it any other way. Some experiences are best felt without inhibition.

After it passed through Block, I followed it to Villa Grove, where it would refuel and spend the night. The anticipated throngs of people made the city close off several streets, and, when I finally found a parking spot, I thought I might walk half the city to see it up close. I was eventually glad I parked so far away due to greater ease of leaving at the end of the night.

When I finally found my way to the mammoth machine’s refueling spot, I marveled at the massive crowds. There were surely several hundred people milling about at once. I’m sure the restaurants and shops were glad to have extra business from those who preceded the train rather than chased and followed it through the countryside. There was also a collection of out-of-town vendors with food trucks and trailers gathered near the Big Boy. A relative who works in the fair, festival, and carnival industry was to be there for the Big Boy, and it was the chance to see him and his family after several years that made me make the first trip. It was very nice to see them, and their strawberry shakeup was delicious.

The following day, I drove west to the marina on Lake Shelbyville in Findlay, Illinois. I rented a pontoon boat and drove (drove? boated? pontooned?) out to the railroad viaduct that bisects the lake and to which there is no automobile access. I anchored my pontoon and prepared for a wait. ….and then I kept moving. It became evident that my anchor line wasn’t long enough to reach the lake’s bottom near the bridge, so I constantly adjusted amongst the other boats to avoid bumping into them. I drifted and waited there for perhaps two hours before the Big Boy came through. I later learned that it had a delayed start in Villa Grove. As I drifted about, I noticed there was quite a crowd of water vessels out to see just the Big Boy. I paid $60.00 for my pontoon and whatever time I would spend seeing it. I later learned that a normal day’s rental is $120.00 for the same pontoon. I think I got a decent deal! There was a wide variety of pontoons, paddle boats, kayaks, speedboats, and even a couple of bi-level boats (maybe yachts, but that seems too big for what these were) eagerly awaiting the locomotive’s run-by. A news helicopter flew overhead shortly before the run-by, and a couple of individuals had camera-equipped drones whizzing about.

Finally, the X4014 4-8-8-4 steam locomotive’s whistle was heard in the distance, and people about the bridge clapped and cheered in anticipation. The helicopter disappeared over the tree line, reappeared, and hovered beyond the west end of the viaduct. The drones whizzed up and away, and we heard the pounding of the wheels on the rails. The Big Boy broke through the tree line and blew her whistle, loud and proud. I was glad I’d drifted about and finally had a good spot a distance from the viaduct rather than up close like yesterday evening. Even at a distance, that powerful whistle made my ear drums vibrate! I got an excellent view of the whole train, front to end, as it crossed and shimmered on the viaduct in the sunlight. One couldn’t have asked for a better day with better weather!

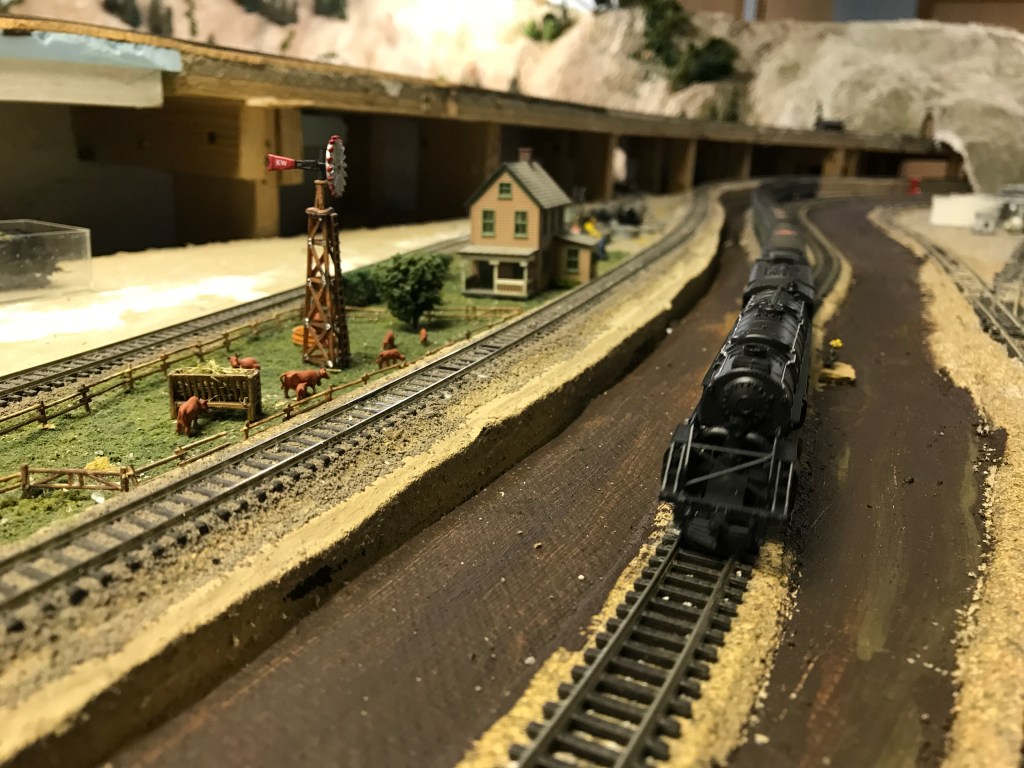

Reverse

Reverse

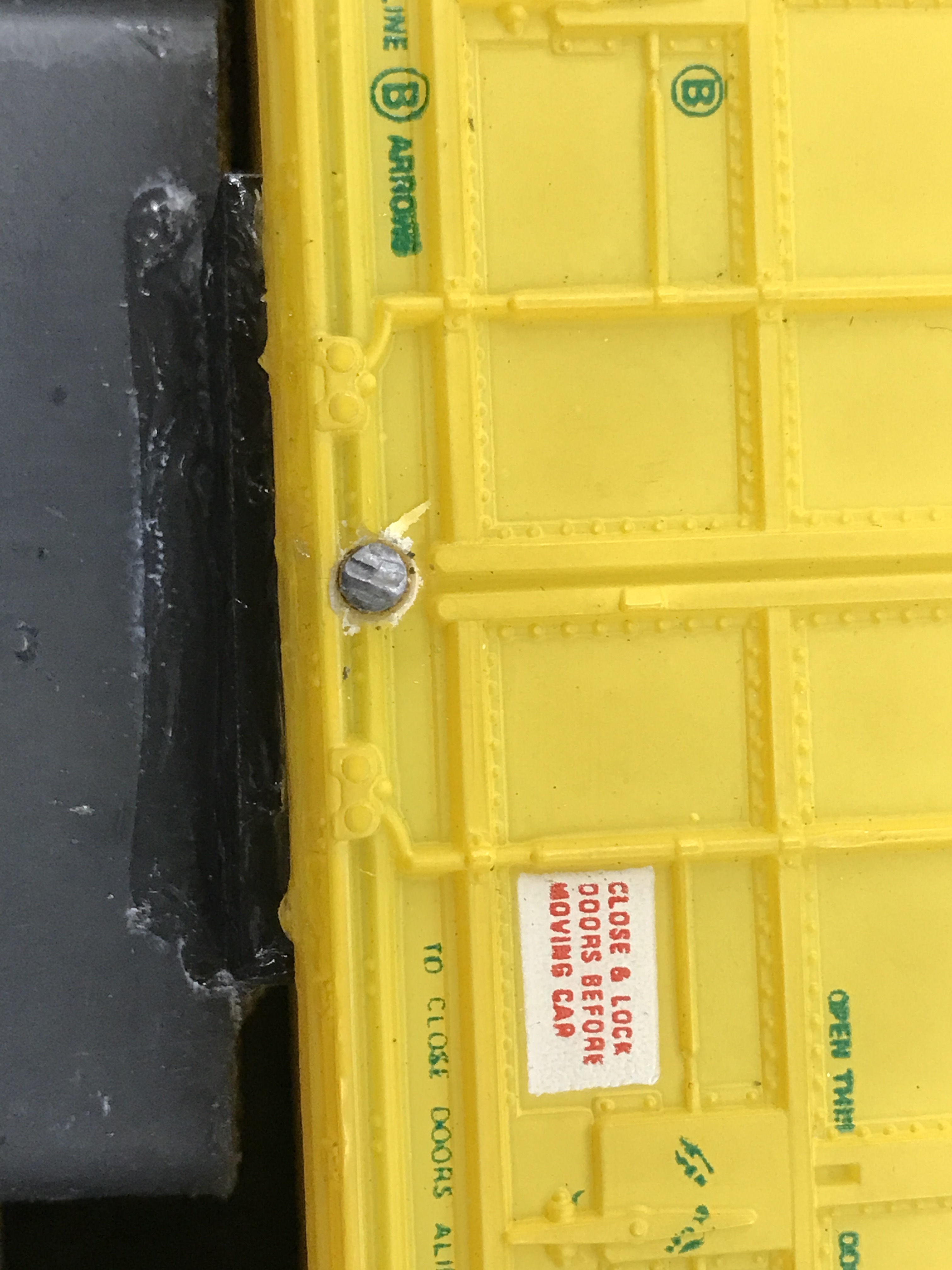

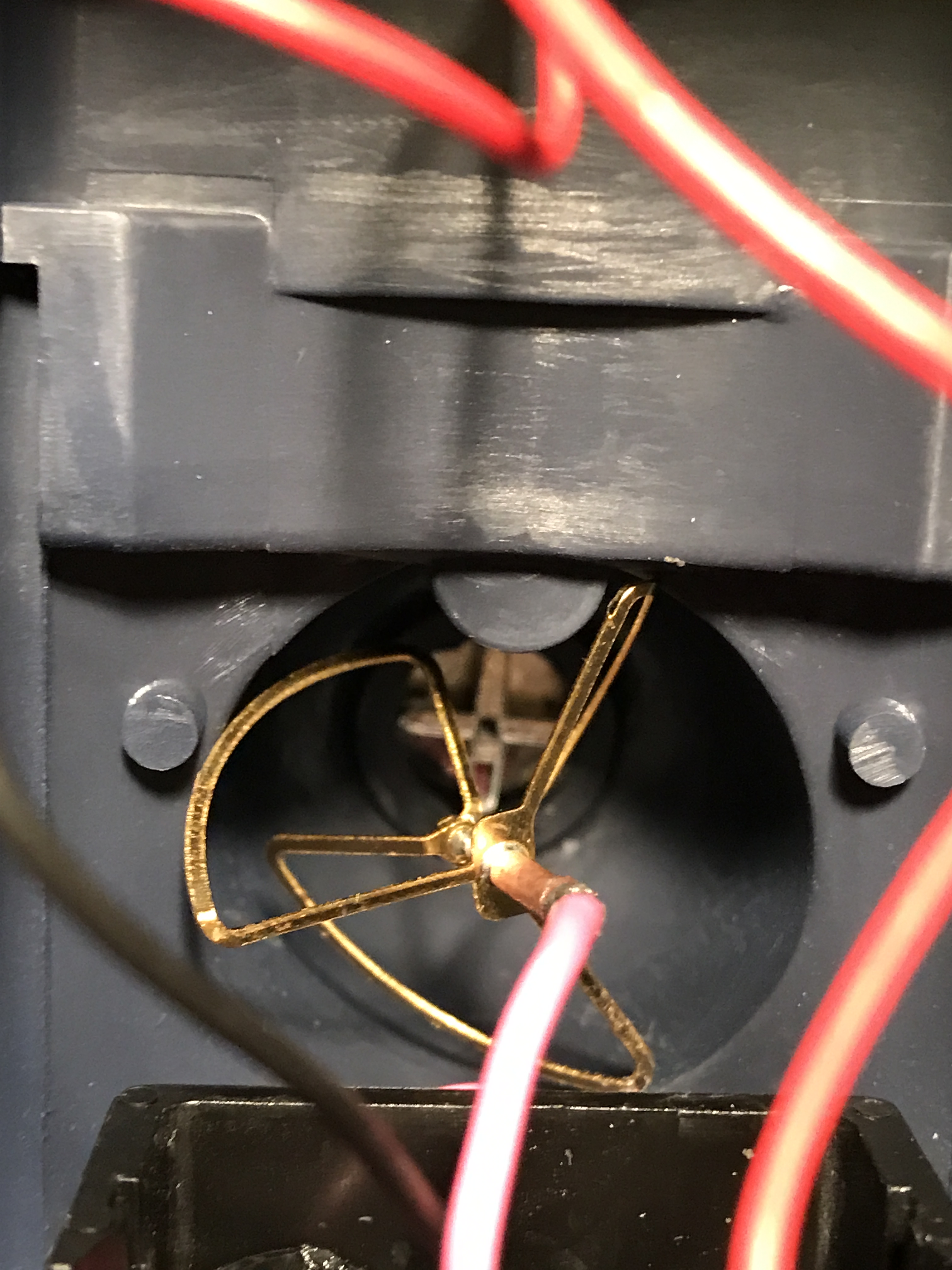

Isn’t it funny how such comparatively small pieces of metal can connect a consist of locomotives and cars for miles?

Isn’t it funny how such comparatively small pieces of metal can connect a consist of locomotives and cars for miles?

This was even more of a surprise! Even my friend who doesn’t really know trains knew this locomotive. I noticed that it was on a set of rails completely disconnected from other tracks. It’s been completey retired from service since September of 2017.

This was even more of a surprise! Even my friend who doesn’t really know trains knew this locomotive. I noticed that it was on a set of rails completely disconnected from other tracks. It’s been completey retired from service since September of 2017.

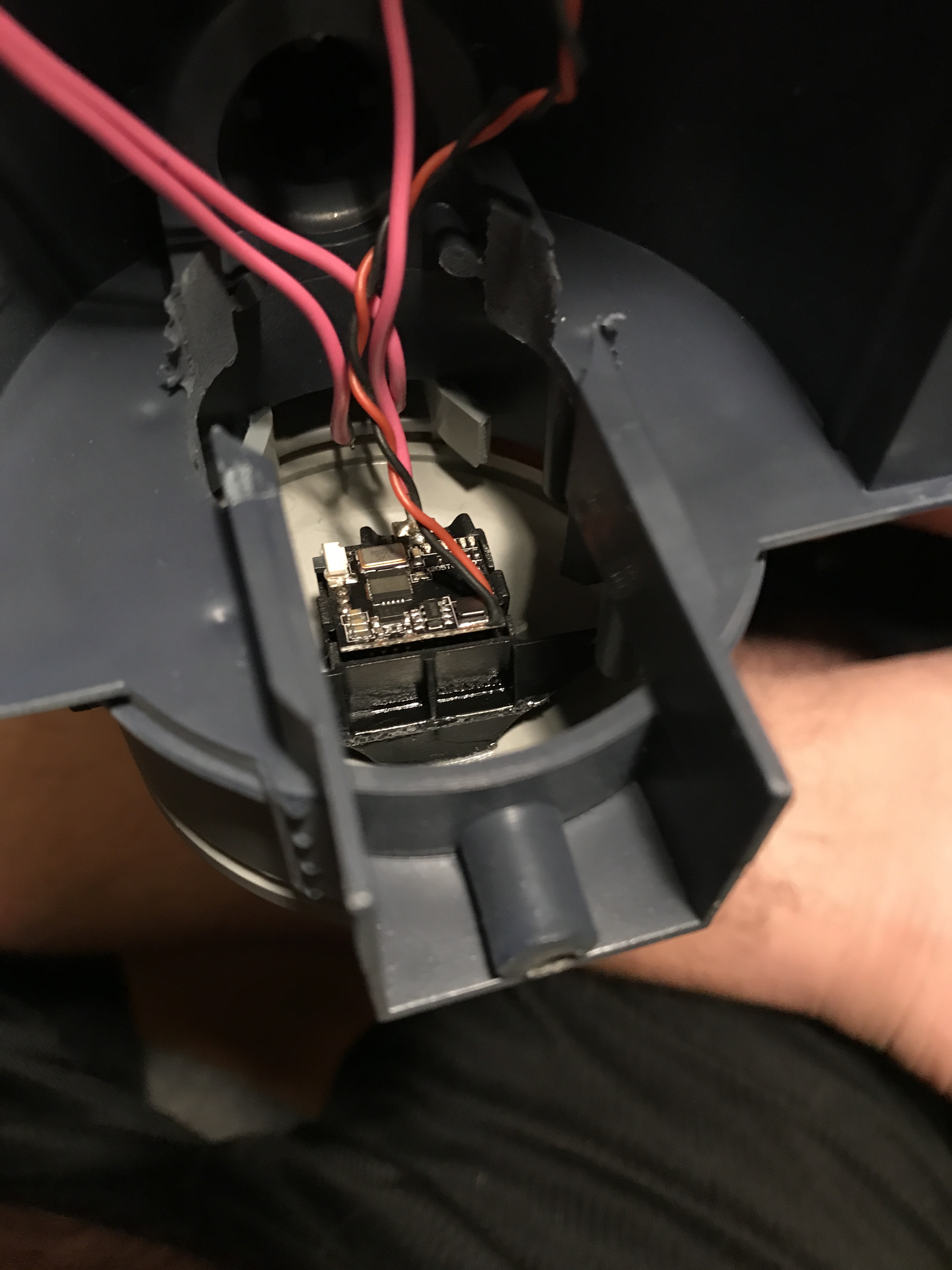

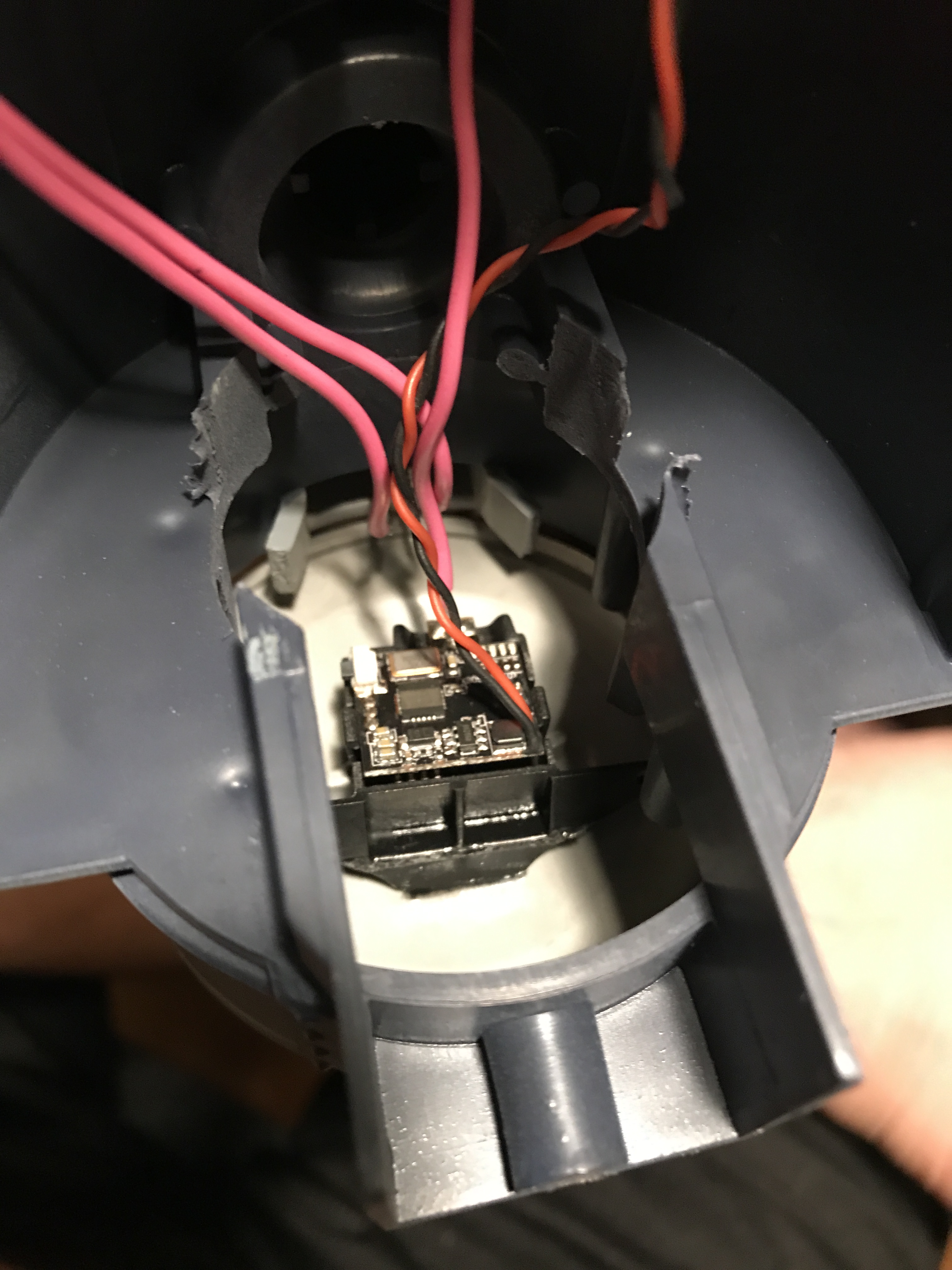

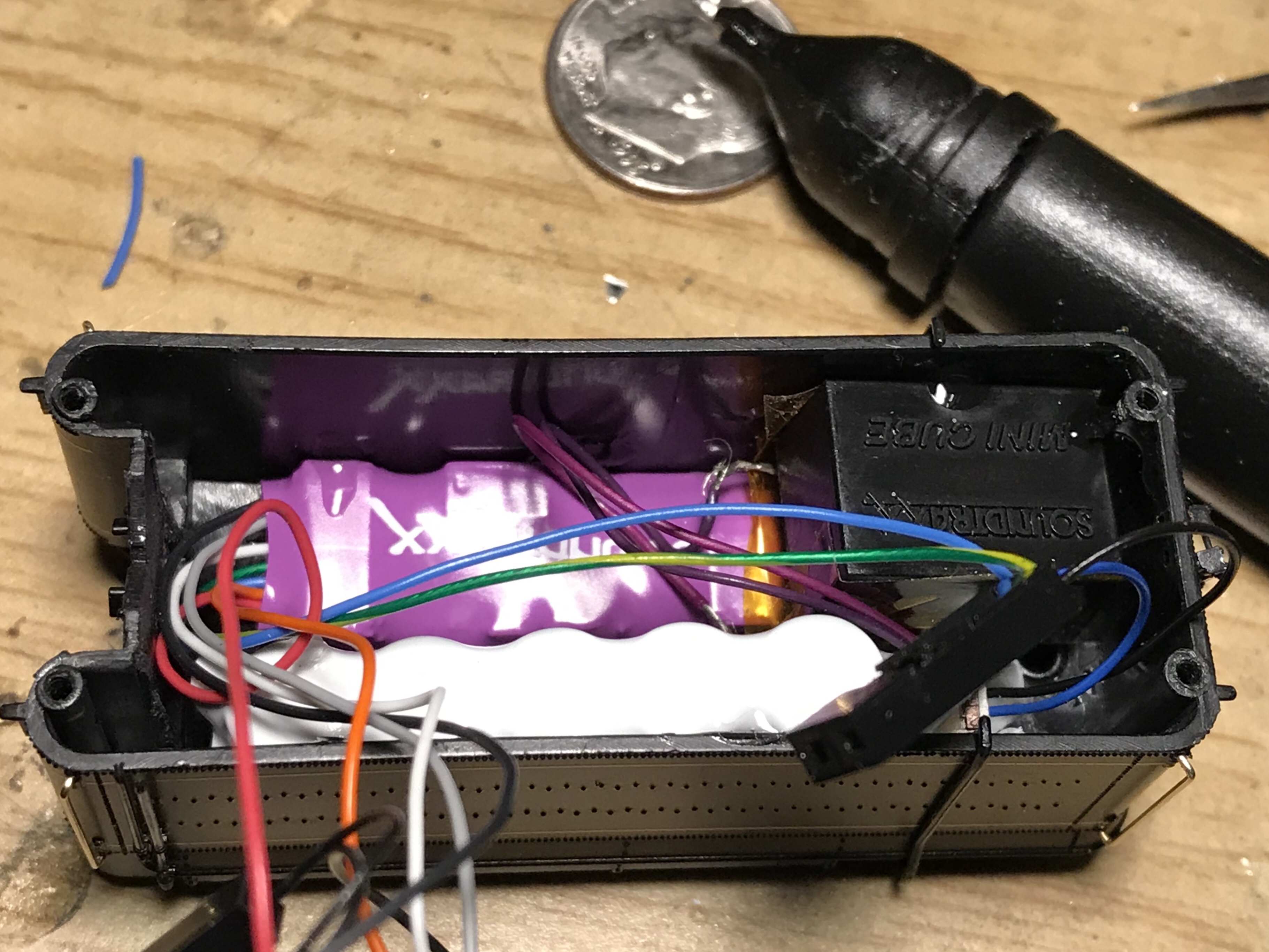

Not in the photo is a makeshift wooden sprung bumper that I installed for the camera’s safety. If this were to fall any distance and land face first, the camera would surely be ruined. The bumper extends about an inch from the frontmost point of the engine shell. I dismantled a couple of mechanical pensils and used their lead casings, springs, and a piece of basla wood as buffers.

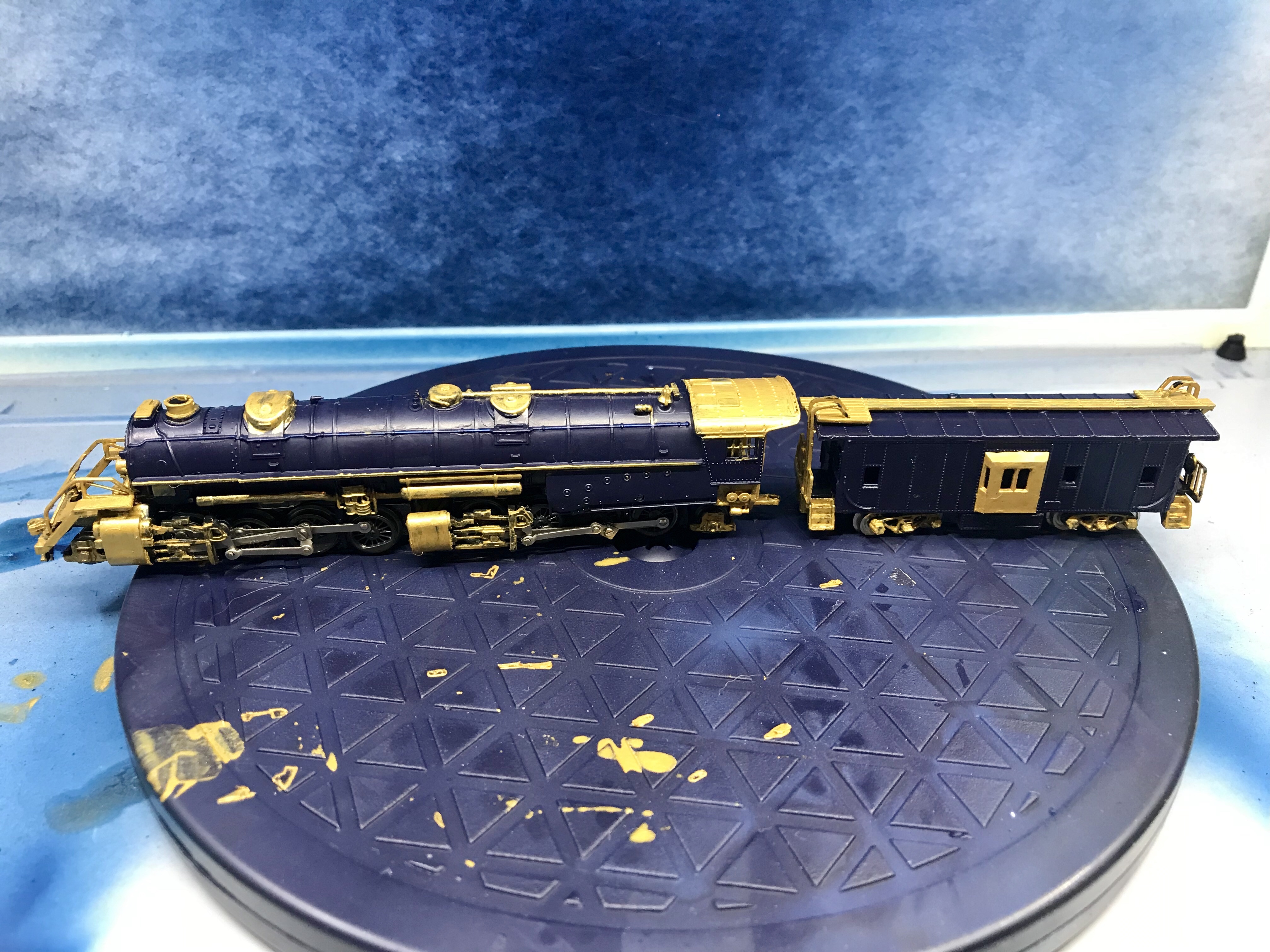

Not in the photo is a makeshift wooden sprung bumper that I installed for the camera’s safety. If this were to fall any distance and land face first, the camera would surely be ruined. The bumper extends about an inch from the frontmost point of the engine shell. I dismantled a couple of mechanical pensils and used their lead casings, springs, and a piece of basla wood as buffers. It just happened that the propogating antenna was the perfect size to fit in the steam locomotive’s dome. I was going to run wiring through the cab, but this saves on wiring going every which way.

It just happened that the propogating antenna was the perfect size to fit in the steam locomotive’s dome. I was going to run wiring through the cab, but this saves on wiring going every which way.